Our overall sustainability strategy underscores the critical importance of effective waste management. We are committed to reducing our environmental footprint by avoiding waste entering landfills and following eco-friendly, end-of-life disposal or recycling processes through authorised vendors.

As a service-oriented company, our waste generation is limited to non hazardous waste from domestic activities and hazardous waste, such as E-waste and batteries, from our service equipment. We rely on suppliers for these equipment, limiting our control over their waste footprint. Moreover, our intangible products results in negligible waste generation at the customer side. Nevertheless, we are committed to reducing waste impacts by ensuring efficient and environmentally sound disposal. Non-hazardous waste is directed to municipal collection or recycling centres, while hazardous waste is disposed of responsibly through authorised recyclers.

Our current circularity measures include composting organic waste, with plans underway to broaden these measures and integrate a circularity model into our operations, aligning with our long term goal of zero waste to landfill by FY 2027. We leverage an internal automated tool and facility-level data records to track and manage waste in compliance with national and local regulations.

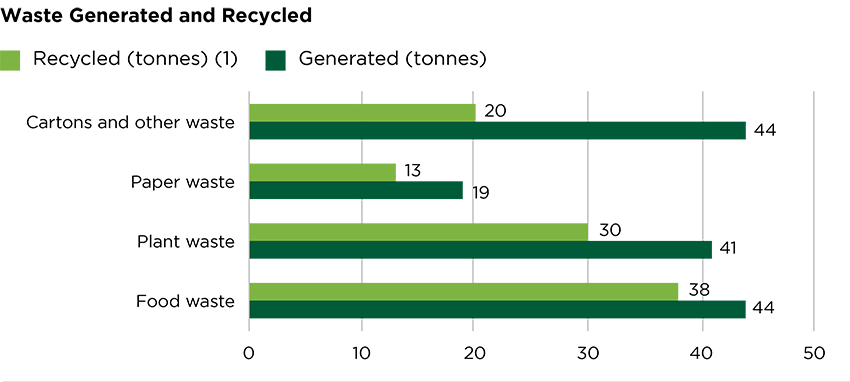

The food waste generated from our cafeterias is converted into manure using Organic Waste Converters (OWCs) at our facilities. This year, we have recycled 67% of our municipal solid waste through in-house OWCs and third-party recyclers. We have completely prohibited the use of single-use plastic on our sites and replaced it with sustainable alternatives, such as glass bottles and reusable ceramic or acrylic mugs.

Food and plant waste composted

Non-hazardous waste recycled

Municipal solid waste generated

Waste disposed

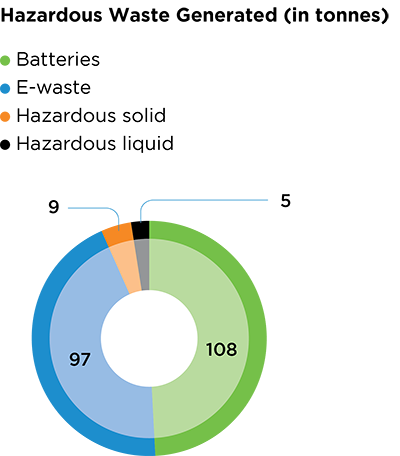

Our facilities generate hazardous waste, including used oil, oil filters, oil-soaked cotton, batteries and e-waste from electronic equipment. To ensure the safe collection and handling of such waste, we offer the requisite awareness and training to our waste handlers. Also, we store that waste in secure facilities with secondary contaminants. All the hazardous waste is recycled through authorised recyclers and processors, such as the Metal Scrap Trade Corporation Limited in India, in compliance with all regulatory requirements of waste management rules in relevant regions or countries.

Hazardous waste generated

Our Chennai facility exemplifies our dedication to environmental sustainability and promotion of innovative thinking with a positive impact on local wildlife. We proactively engaged in water conservation measures and provided support for bird conservation initiatives.

We reused effluent water for horticulture, which significantly reduced costs and recycled water. Bird water bowls were made by our internal design team using inventive upcycling of leftover materials. By reusing the covers of old street lights, we minimised waste and reduced the need for new materials. The team carefully inspected, cleaned, and placed these water bowls across open spaces on-site, ensuring a reliable water source for birds during harsh summers.

We have launched an advanced online checklist model across 7 key locations throughout India, as part of a pilot project covering PAN India. Our strategy involved optimising resource allocation for the development of the online system and conducting comprehensive training for both staff and management. Notably, the integration of QR codes into the checklist streamlined the validation process. This initiative signifies a substantial step towards efficiency and technological innovation in our operational processes.

Paper savings from digital checklists

paper ream saving