Our approach to occupational health and safety (OH&S) is proactive, focusing on risk mitigation strategies, especially for our employees and contract workforce. We adopt technology and form strategies to reinforce our safety protocols. In India, we have implemented an Integrated Management System (EOHS-MS) aligned with the Tata Group Health and Safety Management System, ISO 45001:2018, and ISO 14001:2015 Standards in our facilities, both domestic and international, based on key parameters such as workforce size, ownership, inherent H&S risk and strategic or customer-driven H&S requirements. Consequently, we have fully incorporated the H&S Management System in all (100%) our major facilities in India (10 in total) and in key international facilities (3 in Canada, 2 in Singapore and 1 in Australia).

As a part of management system implementation, we have defined organisational structure, responsibilities, procedures, processes, and resources for developing, implementing, achieving, reviewing and maintaining the organisation’s OH&S policy and other commitments. The management system includes the well-being and safety of our employees, subcontractors, visitors and neighbouring communities. These systems provide a structured framework for effectively managing Environment, Occupational Health & Safety (EOHS) risks and promoting a culture of continuous improvement.

All our workplaces are designed with ergonomic comfort, safety and workforce security in mind. Each site is hazard-free with proper illumination, reduced noise, efficient ventilation, hygienic food and water facilities. Medical facilities, resting spaces and visiting doctor services are also available in most locations. We plan an Occupational Health assessment for high-risk activities in FY 2024.

We ensure suitable health insurance and coverage for all our workers, including the contract workforce. This encompasses access to medical facilities, emergency assistance and coverage for occupational health incidents. Worker representation in the H&S committees is assured wherever applicable.

We have an efficient grievance redressal system through our internal EOHS Incident reporting Portal to address any EOHS concerns from employees, subcontractors, or other stakeholders. This mechanism provides a platform to report incidents, hazards, or other EOHS issues. We are dedicated to promptly investigating and resolving these concerns, taking corrective measures to prevent future incidents and continually enhancing our EOHS practices.

Our leaders set a strong precedent for our ‘Zero Harm’ objective. Our approach, outlining roles and responsibilities for leadership, is clearly defined in the EOHS – MS Apex Manual. Some of the key measures that reflect our leadership’s commitment to our Health & Safety Management system include:

MD & CEO’s approval of the OHS Policy, release of safety communications, and endorsement of the short-term Health and Safety objectives.

The leadership team proposed and increased the remit of the existing Board-level CSR committee to add Safety and Sustainability elements.

The establishment of a Global Safety Council (GSC) that conducts quarterly safety performance reviews, which comprises senior management and relevant business function heads; the GSC ensures adequate resources, operational level performance reviews and the sharing of best practices.

Active participation of the leadership team in safety events like Safety Carnival, including the release of promotional videos.

Apart from a formal ISO 45001-based management system, the Company has implemented its H&S Management processes and programmes based on a risk-based approach for all its operations worldwide. The risk-based approach, processes and programmes have helped the Company eliminate or minimise the impacts and risks and explore new opportunities in operational activities and services that come along with our activities and cover all employees (including employees engaged by the sub-contractors) and other interested parties such as visitors, neighbouring communities and stakeholders. The key safety focus areas are defined below.

Each business unit is responsible for identifying hazardous activities and conducting a comprehensive hazard identification and risk assessment (HIRA) for each of their activities. The assessment involves breaking down each activity into individual steps and evaluating the risks associated with each step. Control measures are then proposed and implemented accordingly.

We have made it mandatory to carry out HIRA activities once every three years, with their effectiveness being assessed through annual internal audits and ISO 45001 surveillance audits. All audit findings are being tracked internally, along with the identification of corrective actions with established and pre-defined timelines. The findings are closed and implemented horizontally, with their effectiveness checked.

We leverage technology and follow various standards to address issues related to health and safety at the workplace. All these interventions are identified based on a risk-based approach.

We enforce safety through a robust audit programme. Last year, we conducted a total of 16,901 (361 EOHS and 16,540 BU) team audits team audits, encompassing both internal and external assessments. All findings were resolved within the year, contributing to improved safety standards and ISO 45001 certification maintenance.

All our high-risk activities require a valid work permit obtained via our e-PTW mobile app or web portal. The permits are raised by onsite workers and are reviewed and approved by an On Roll employee (the Manager) after their review of the site and working conditions.

We issue an e-safety passport post requisite training, ensuring our staff’s preparedness for field operations. The passport reflects the valid training and skills of our contract workforce.

We have installed DBM devices in all field operation vehicles (4-wheelers), providing vital data on driver behaviour. This initiative has significantly reduced speeding violations.

At our Dighi campus, we have deployed an Automatic Speed Detection System (ASDS) to monitor vehicle speeds, enhancing safety within the campus.

This automated solution enables our EOHS teams to streamline HSE programmes, including incident reporting, audit management, reward systems, and the Company’s MIS system.

This application helps in monitoring vehicle speed, distance travelled, and PPE usage, leading to a 75%+ drop in speed bursts, thereby increasing overall safety.

Our Suppliers are obligated to meet EOHS requirements as referred in Supplier Code of Conduct. Further, service contractors working with us are obligated to comply with Mandatory Safety Standards (MSS)

Tata Communications prioritises safety as a condition of employment for all contractors and subcontractors. We have an Incident Reporting System to report and investigate all incidents as per our defined SOP. The system has well-laid procedures for reporting, investigation, and corrective actions, with a no-reprisal mechanism for employees and the contract workforce. Sharing safety lessons helps prevent future incidents.

It helps report, track and investigate all workplace unsafe observations, including injuries and illnesses, spills, property damage and vehicle incidents, among others;

It helps the respective Business Health & Safety (H&S) SPOCs and the (EOHS) team review the root cause, develop a corrective action plan and share learnings with all

It enables everyone to swiftly report any unsafe practices, behaviour or incidents within the facility and also in other areas of operations outside office premises.

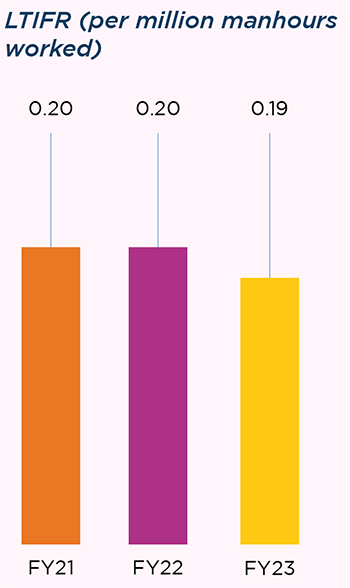

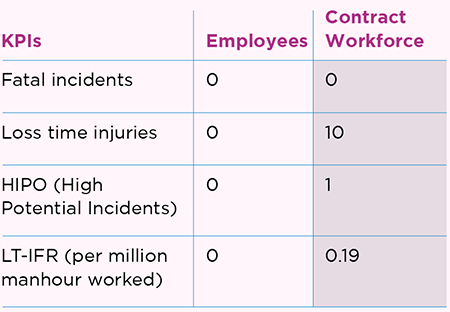

Maintaining the well-being and safety of our employees and contractors remains our utmost priority. We ensure safety through audits, extensive training, and a reduction of 5% in the Lost Time Injury Frequency Rate (LTI-FR) as compared to the previous fiscal year. SPOCs conduct audits and investigate incidents and thoroughly investigate incidents and promptly close the reported incidents by circulating the lessons learned to all the internal stakeholders across all BUs.

Safety observations reported

Training sessions conducted

Participants trained

Each business unit is accountable for identifying hazards and conducting a thorough hazard identification and risk assessment (HIRA) for each hazardous activity. This involves evaluating risks at each step and implementing suitable control measures. All audit findings are internally tracked, with corrective actions and deadlines defined. Once closed, these findings are implemented across units and their effectiveness assessed.

We follow the Plan-Do-Check-Act Model according to the EOHS Management system wherein the OHS Policy, Objectives and Targets and its management plans are periodically updated based on the inputs and feedback of interested parties, changes / updates in legal compliances, business concerns and activities. The implementation and progress on the identified OHS plans, risks and opportunities are being discussed and reviewed periodically by the EOHS & Sustainability team along with the various Business Functions (having an EOHS Interphase) as part of BU Routines and Management Review meetings. Further, the Senior leadership team involving the CHRO and MD & CEO reviews the OHS performance and guides the team with their specific feedback and inputs for further improvement and implementation and the results of the same are discussed at the Board level CSR, Safety & Sustainable Development committee for continual improvement.

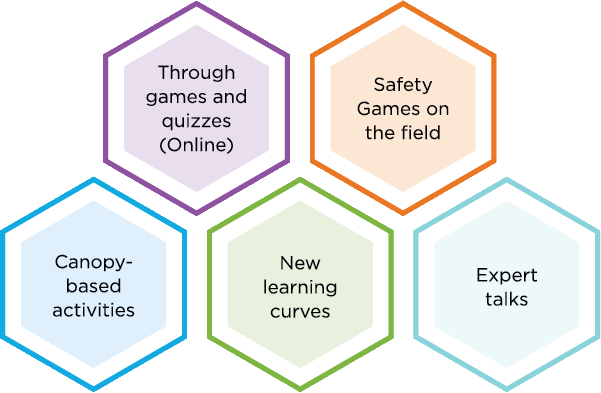

The Safety Carnival 2023 aimed to promote Occupational Health & Safety culture and sustainability principles. Tailored to each business unit, it featured virtual and physical events, promoting safety awareness and a secure working environment. The event was a success, promoting the ‘OUR AIM-ZERO HARM’ theme as a part of Indian National Safety Day.

Employees targeted

coverage in all facilities

The Dighi campus is spread over 692 acres and employs approximately 4,000+ employees. We provide our employees with a pick-up and drop-off facility across Pune city and about 2,200 employees avail themselves of the facility. The total number of vehicles deployed for this purpose is 200+.

The operation was at risk from frequent over speeding and safety breaches as passengers on two-wheelers did not wear helmets and those on four-wheelers did not wear seat belts or frequently used their mobile phones while driving. There was also low safety awareness among transport drivers.

Construction of pedestrian pathways and widening of roads

Additional speed breakers to control vehicle speed

Regular safety awareness briefings for our drivers as well as those working for our vendor partners

Introduction of Dighi safety standards, including the laying down of speed limits, emphasis on the use of helmets, safety belts and a ban on mobile phone use while driving.

Deployment of the Automatic Speed Detection System (ASDS), a video-based monitoring system that tracks down any vehicle crossing the speed limit of 30 kmph.

The deployment of ASDS has helped with adherence to speed limits and safety risk reduction at the Dighi campus.